Understanding steel wire armoured cable and its impact in electrical engineering

Discovering the Different Types of Armoured Cable and Their Applications

Armoured wires are vital parts throughout numerous industries, using protection and reliability. Different types, including Steel Cord Armoured (SWA) and Aluminium armoured cable televisions, provide to particular requirements based on environment and application. Insulation products like PVC and XLPE additionally enhance their performance. Recognizing these differences is vital for picking the best wire. The ramifications of these choices can substantially affect functional efficiency and safety and security in diverse markets. What aspects should one consider when making such decisions?

Summary of Armoured Cable Television Kind

For instance, the PVC armoured cable is generally used in outdoor atmospheres as a result of its resistance to dampness and chemicals. The XLPE armoured cable, with cross-linked polyethylene insulation, is acknowledged for its high thermal security and electric efficiency, making it appropriate for industrial setups. An additional type is the AWA (Aluminum Cable Armoured) cable, often utilized in underground setups where light-weight homes are advantageous. Comprehending the numerous armoured wire kinds allows specialists to select the most suitable option for their certain demands, guaranteeing security and reliability in electric systems.

Steel Cord Armoured (SWA) Wire

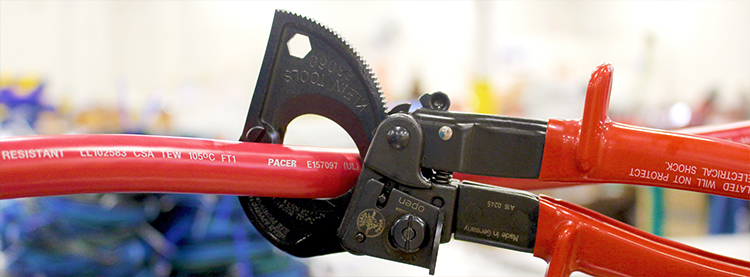

Steel Cord Armoured (SWA) cable television is a durable option created to endure severe ecological problems and mechanical stress and anxiety. This sort of cord includes a layer of steel cord that gives considerable protection against impact, moisture, and chemical exposure, making it excellent for industrial and outdoor applications - armoured cable. The building usually includes a copper or aluminium conductor, protected with PVC or XLPE, and surrounded by a steel cable armour layer

SWA cords are commonly utilized in power circulation networks, where their durability warranties reliable solution in tough setups. They are commonly used in underground setups, building websites, and locations where cable televisions might be subjected to physical damages. In addition, SWA cable televisions sustain both reduced and high voltage applications, enhancing their adaptability. Their capacity to withstand rust and mechanical wear makes them a favored option for several engineers and service providers when picking cable television services for requiring environments.

Aluminium Armoured Wire

Aluminium armoured wire offers a light-weight yet long lasting choice to standard steel cable armoured cords, making it ideal for different applications. This kind of cord is frequently made use of in business and commercial settings, where flexibility and simplicity of installment are extremely important. Its reduced weight promotes handling, lowering the labor prices connected with setup.

Aluminium armoured cables are specifically beneficial in atmospheres that require defense against mechanical damage, dampness, and chemical direct exposure. They are commonly used in power distribution, underground setups, and outside applications, showcasing their adaptability. Furthermore, the deterioration resistance of aluminium boosts the durability of the cord in extreme problems.

The use of aluminium likewise adds to cost-effectiveness, as it is generally more economical than steel. armoured cable. Overall, aluminium armoured wire represents a useful choice for requiring electric systems, combining efficiency, defense, and financial advantages

PVC vs. XLPE Shielded Armoured Cables

When comparing shielded armoured cables, PVC (Polyvinyl Chloride) and XLPE (Cross-Linked Polyethylene) stick out as 2 favored products, each offering distinct advantages for specific applications. PVC is recognized for its excellent mechanical properties and cost-effectiveness, making it a prominent selection for general-purpose wiring. It supplies great insulation click here to read and resistance to chemicals, though it might have limitations in temperature level tolerance and adaptability. In contrast, XLPE boasts exceptional thermal resistance and appropriates for higher temperature atmospheres, making it ideal for applications calling for high efficiency and longevity. XLPE insulation also improves electric residential properties, providing lower dielectric loss and boosted energy effectiveness. While PVC cable televisions are usually utilized in residential and business installments, XLPE cable televisions are favored in commercial and energy setups where effectiveness and dependability are critical. Ultimately, the selection in between PVC and XLPE depends upon the details demands of the setup atmosphere and the desired efficiency qualities.

Applications of Armoured Cables in Different Industries

Armoured cords, with their robust building and construction and safety features, locate comprehensive use across various markets. In the construction sector, they provide trustworthy electrical connections in harsh settings, guaranteeing safety and toughness. The telecommunications sector makes use of armoured wires to secure information transmission lines from physical damages, particularly in outdoor setups. In mining and quarrying, these wires are important for powering heavy equipment and devices, where exposure to rough problems is common. Additionally, the oil and gas sector uses armoured wires to maintain operational integrity in tough settings, including overseas systems. The sustainable energy market likewise advantages, as these wires are considerable for wind and solar ranches, attaching numerous parts while enduring environmental stressors. In general, armoured cable televisions are vital for making sure undisturbed service, safeguarding infrastructure, and boosting functional efficiency throughout diverse applications.

Regularly Asked Questions

Exactly how Do I Choose the Right Armoured Cable for My Task?

Picking the right armoured cord entails evaluating task specifications, consisting of environmental conditions, electrical load demands, and setup place. Consulting market websites requirements and seeking specialist suggestions can likewise ensure appropriate option for safety and security and efficiency.

Can Armoured Cables Be Used Outdoors and Underground?

Armoured wires can undoubtedly be used outdoors and underground. Their durable building safeguards against environmental factors, wetness, and physical damages, making them suitable for numerous installations, consisting of those revealed to harsh climate condition or underground settings.

What Is the Life Expectancy of Armoured Cables?

Armoured cables normally have a life expectancy of 25 to three decades, relying on ecological conditions and installment techniques. Proper maintenance and security from severe problems can additionally enhance their toughness and long life.

Are Armoured Cables Resistant to Chemical Exposure?

Armoured wires display varying degrees of resistance to chemical exposure, depending on their insulation products. Typically, certain kinds endure chemicals far better than others, making it vital to choose proper cords for certain environments and applications.

Exactly How Do Armoured Wires Deal With Temperature Level Fluctuations?

Armoured cable televisions are created to endure temperature level fluctuations effectively. Their robust building enables them to keep efficiency and insulation integrity throughout differing temperature levels, making pop over to this web-site them ideal for varied atmospheres and lowering the threat of damages.

Various types, including Steel Wire Armoured (SWA) and Aluminium armoured wires, provide to certain requirements based on setting and application. Armoured cable televisions are crucial components in numerous electrical installations, giving enhanced defense versus mechanical damage and environmental aspects. Aluminium armoured wire supplies a lightweight yet sturdy alternative to conventional steel cable armoured cable televisions, making it appropriate for different applications. When contrasting protected armoured cords, PVC (Polyvinyl Chloride) and XLPE (Cross-Linked Polyethylene) stand out as 2 extensively used products, each offering unique advantages for certain applications. While PVC cords are typically made use of in industrial and property setups, XLPE cables are preferred in commercial and energy settings where toughness and dependability are paramount.